From Fossil Fuels to Bio-Refining: Is the Industry Ready to Transition?

For over a century, oil refineries have been the backbone of the global energy infrastructure—transforming crude oil into fuels, lubricants, and raw materials essential to modern life. But as climate change accelerates and policy pressure mounts, the question facing the refining industry today is no longer if it should change, but how fast and how far it can transition to sustainable alternatives. One of the most promising pathways? Bio-refining.

What Is Bio-Refining?

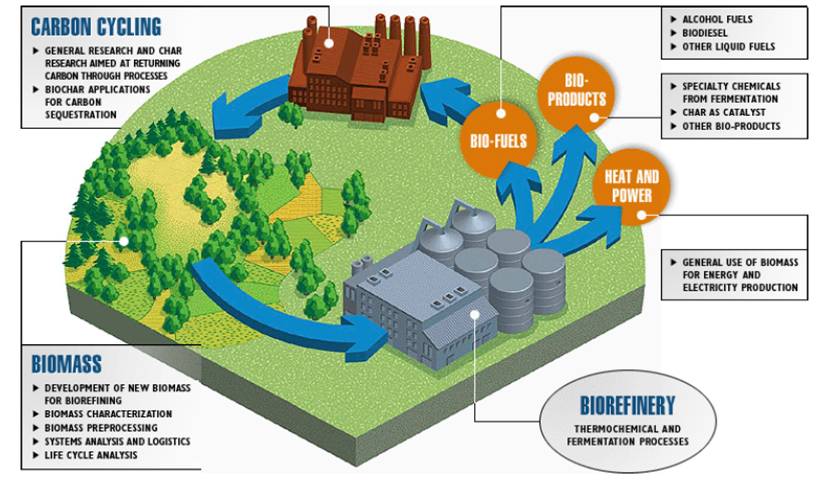

Bio-refining is the process of converting biomass—organic materials like agricultural waste, forest residues, or algae—into fuels, chemicals, and power. Much like a traditional oil refinery, a bio-refinery integrates multiple conversion processes. However, instead of relying on fossil fuels, it taps into renewable, carbon-neutral resources.

The end products can include:

-

Renewable diesel and bio-jet fuel

-

Bioplastics

-

Green chemicals (like bio-methanol, bio-butanol)

-

Power and heat

Why Transition Now?

1. Climate Mandates and Net-Zero Goals

Governments and corporations worldwide are targeting net-zero emissions by 2050. Traditional refining is one of the largest industrial carbon emitters. Bio-refining, by contrast, can significantly reduce lifecycle greenhouse gas emissions, especially when paired with carbon capture and storage (CCS).

2. Policy Incentives

Programs like the U.S. Renewable Fuel Standard (RFS), the EU’s RED II directive, and carbon pricing schemes are creating a favorable economic environment for low-carbon fuel producers.

3. Declining Fossil Fuel Demand

With the rise of electric vehicles, cleaner technologies, and changing consumer behavior, long-term demand for gasoline and diesel is plateauing or declining. Diversifying into bio-based products can safeguard refinery economics.

Challenges Slowing the Shift

Despite the momentum, bio-refining is not without hurdles:

Technical Complexity

Biomass feedstocks are chemically diverse and harder to process consistently compared to crude oil. Converting existing infrastructure to handle them is expensive and requires significant R&D.

Capital Investment

Retrofitting existing refineries or building new bio-refineries from scratch involves substantial capital. Many companies are cautiously piloting biofuel initiatives before going all-in.

Feedstock Availability and Sustainability

Scaling bio-refining depends on a reliable supply of sustainable biomass. Over-reliance on crops like corn or soy can create competition with food production and raise land use concerns.

Who’s Leading the Charge?

Major energy players like Neste, TotalEnergies, Chevron, and Shell are already investing heavily in renewable diesel and SAF (sustainable aviation fuel) production. Several refineries in the U.S. and Europe have been converted into renewable fuel plants—a trend expected to continue through the 2030s.

So, Is the Industry Ready?

Partially. The refining industry has acknowledged the inevitability of transition and has begun laying the groundwork. However, readiness varies by region, company, and market maturity. Bio-refining is no longer an experiment—it’s a strategic pivot. But to make it mainstream, the industry must overcome feedstock limitations, scale new technologies, and build collaborative supply chains across agriculture, waste management, and energy sectors.

Conclusion

The shift from fossil fuels to bio-refining represents more than just a technological change—it’s a transformation of the entire value chain. For refiners, the challenge is steep, but so is the opportunity. The future of energy is not just low-carbon—it’s bio-based, circular, and innovation-driven. The real question is: Who will lead, and who will lag behind?